Summary of the Research for our Electric Propulsion System

We are now the owners of a power catamaran, one that has no engines. It is therefore necessary to choose the new electric propulsion system and the …

The refit of the Escargot has begun! After four months of hard work by the shipyard workers, we’re excited to share our first major update.

Our primary goal is to have the Escargot back in the water this summer for sea trials, which will allow us to work on the interior refit while afloat. The shipyard is tackling the heavy structural work, while we focus on planning the future: the electric propulsion system, the solar power generation setup, and the general electrical system rebuild.

The first major step was to clear out the port and starboard engine bays. The old, fiberglassed wood beam supports for the diesel engines have been completely removed. This opens up a significant amount of space for the new electric motors and battery banks.

All the necessary fiberglass work below the waterline is now complete. This included extensive repairs, followed by a protective epoxy coating.

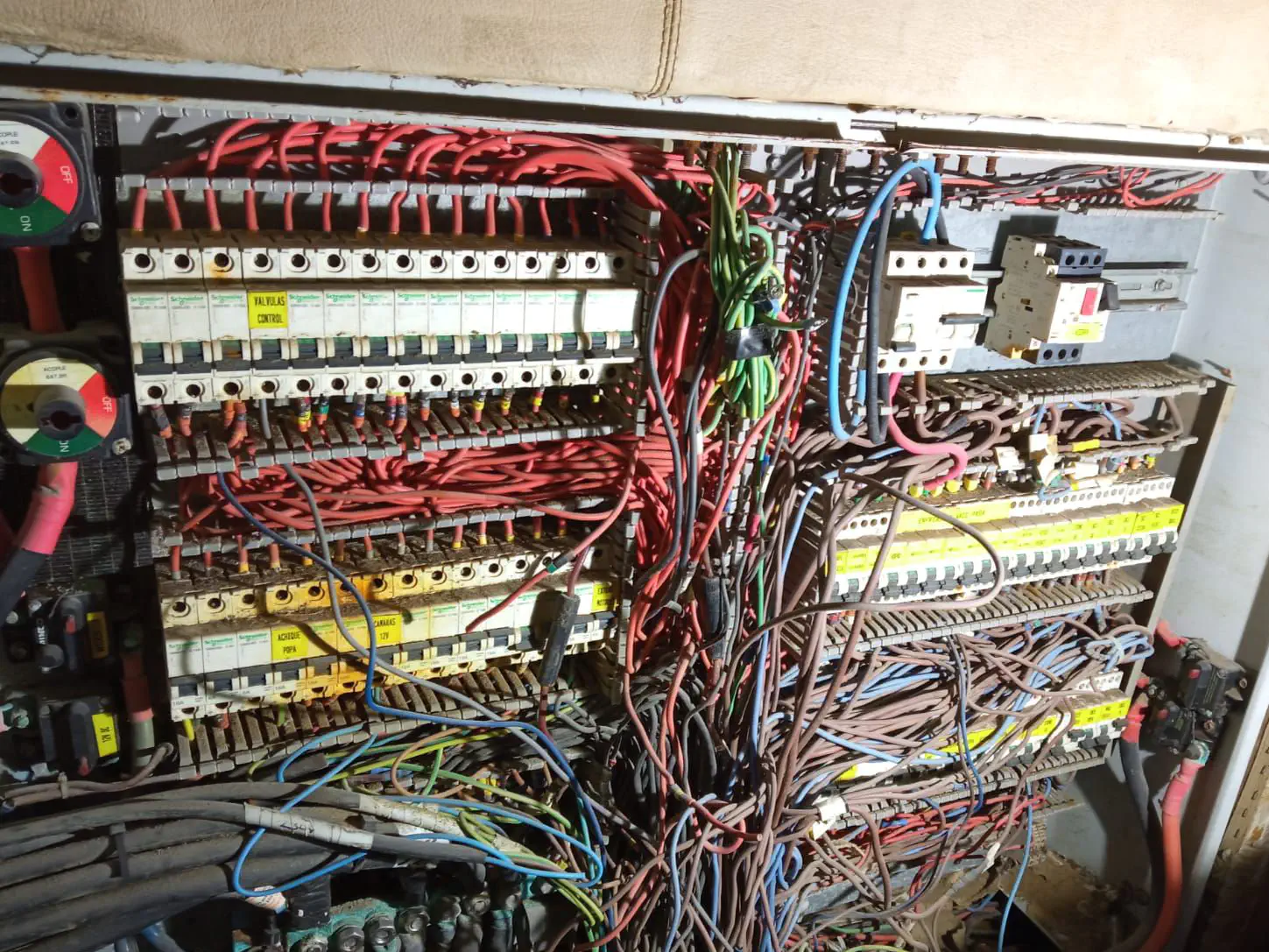

The complete electrical refit has kicked off with brand-new DC and AC panels equipped with new thermal breakers. We are currently assessing the existing wiring to determine what can be safely reused in the new system.

Restoring the unique rounded shape of the aft cabin was a challenge. It required building a custom mold to ensure the new fiberglass work matched the boat’s original and unique curvature.

It’s clear that most, if not all, of the aft cabin windows will need to be replaced. We experimented with in-place thermoforming of a methacrylate sheet to see if we could create new windows ourselves. While the result is acceptable, this process doesn’t quite replicate the original curvature of the glass. We are still evaluating our options here.

We have finalized the location for the new grey water tanks in the engine rooms. To prepare for their installation, we have built, fiberglassed, and painted sturdy new supports. The plumbing for the grey water systems is next on the list.

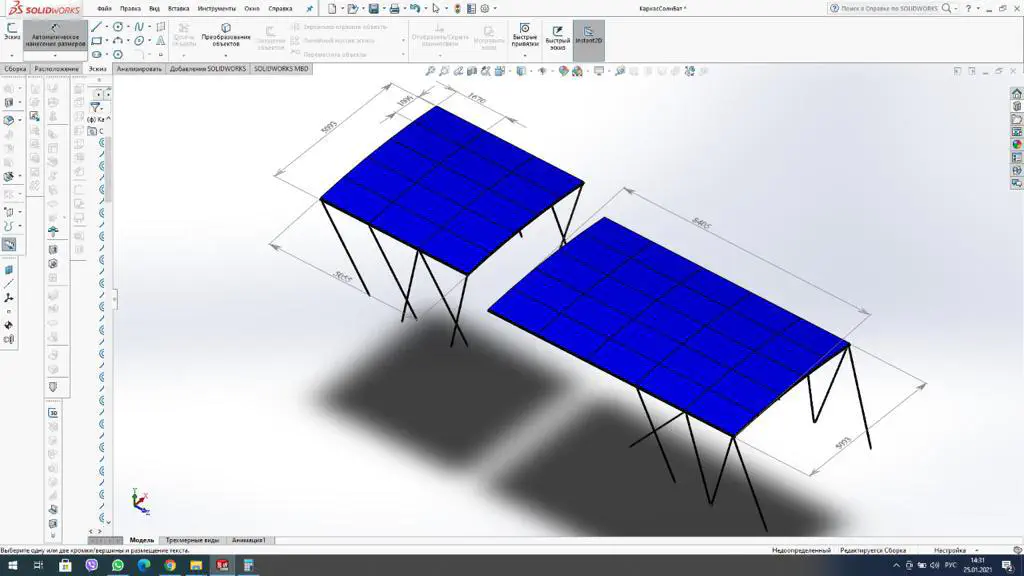

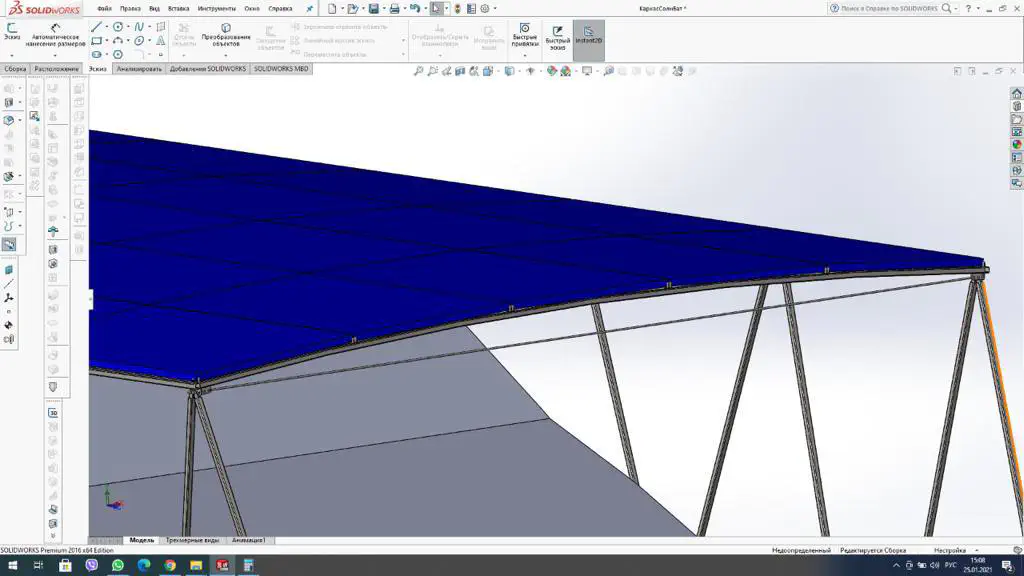

Work isn’t just happening on the boat, but on the drawing board as well. The shipyard engineer has begun designing the superstructure for the solar panels. Before this can be finalized, we need to select the exact make and model of the panels, as their dimensions and mounting points are critical design details.

We’re also deep into the planning and design phases for several other key tasks:

We are now the owners of a power catamaran, one that has no engines. It is therefore necessary to choose the new electric propulsion system and the …

Dean Jag 530 wreck intrigues us ([see the article: The Search for the Ideal Boat for Refit to Electric Propulsion]({{< ref "20200815" >}})) and …