Refit Project Update - Q1 2021

The refit of the Escargot has begun! After four months of hard work by the shipyard workers, we're excited to share our first major update. Our …

The last three months have been a classic refit story of progress and patience. While the pace has been slower than we originally planned, we’ve made huge strides in finalizing critical systems and the heavy structural work on the hulls is now complete.

Unfortunately, a combination of parts delivery delays and a shortage of available workers means we won’t hit our original summer launch target. We are now looking at an October splash date, assuming all goes well from here. Setbacks are part of any major refit, and we’re focused on the exciting progress being made.

The original fancy retracting cleats were clever, but some were broken and they all required complex under-deck drainage pipes. This seemed prone to future problems, so we’ve opted for simplicity and reliability. We removed the old ones and installed robust, classic Vetus Taurus cleats.

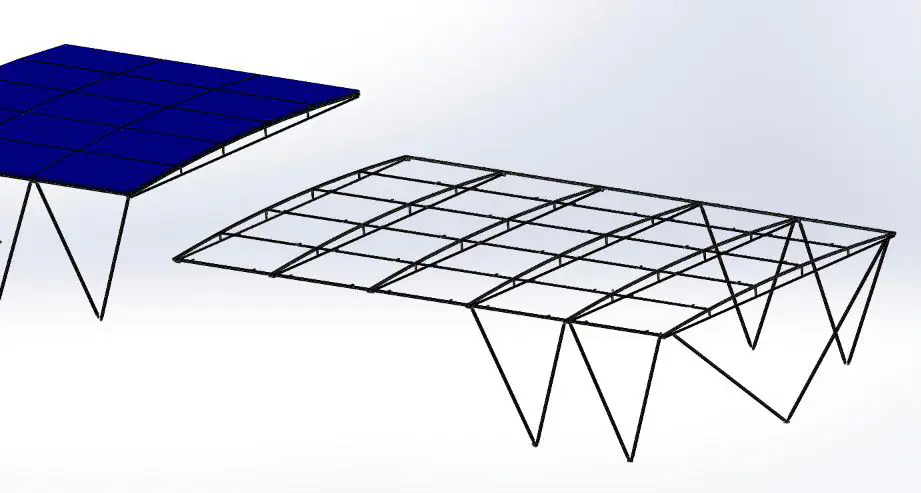

We have finalized the heart of our power generation system: the solar panels. After extensive research, we couldn’t find European-made panels.

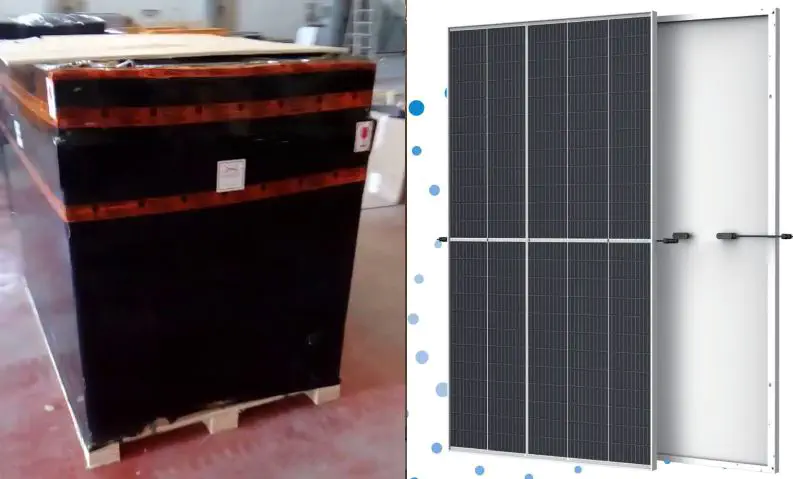

We placed an order for a palette of 42 Trina Solar Vertex S TSM-395-DE09.08 panels from a reseller in Germany. These are the new high-performance panels from a leading manufacturer, designed for residential and commercial installations.

Standard marine solar panels are much smaller and usually less efficient, making them unsuitable for the large, powerful array we need to be fully self-sufficient.

Major components for the new electric propulsion system have started to arrive, and we’re making progress on the rudders.

New Rudders To be resourceful, we’ve repurposed one of the old propeller shafts to create our new rudder shafts. Our metal shop prepared the shafts and fabricated the additional components needed to connect them to the hydraulic steering cylinders.

Propulsion Parts Arrive We were excited to receive the Python Drive thrust bearings and the new propellers. The thrust bearings are a critical component, installed on the propeller shaft to transmit the propeller’s thrust directly to a reinforced bulkhead in the hull, rather than to the electric motor.

The delivery of the new Vetus 50mm shafts and stern tubes means we now have all the major parts on hand to install the complete propeller shaft lines.

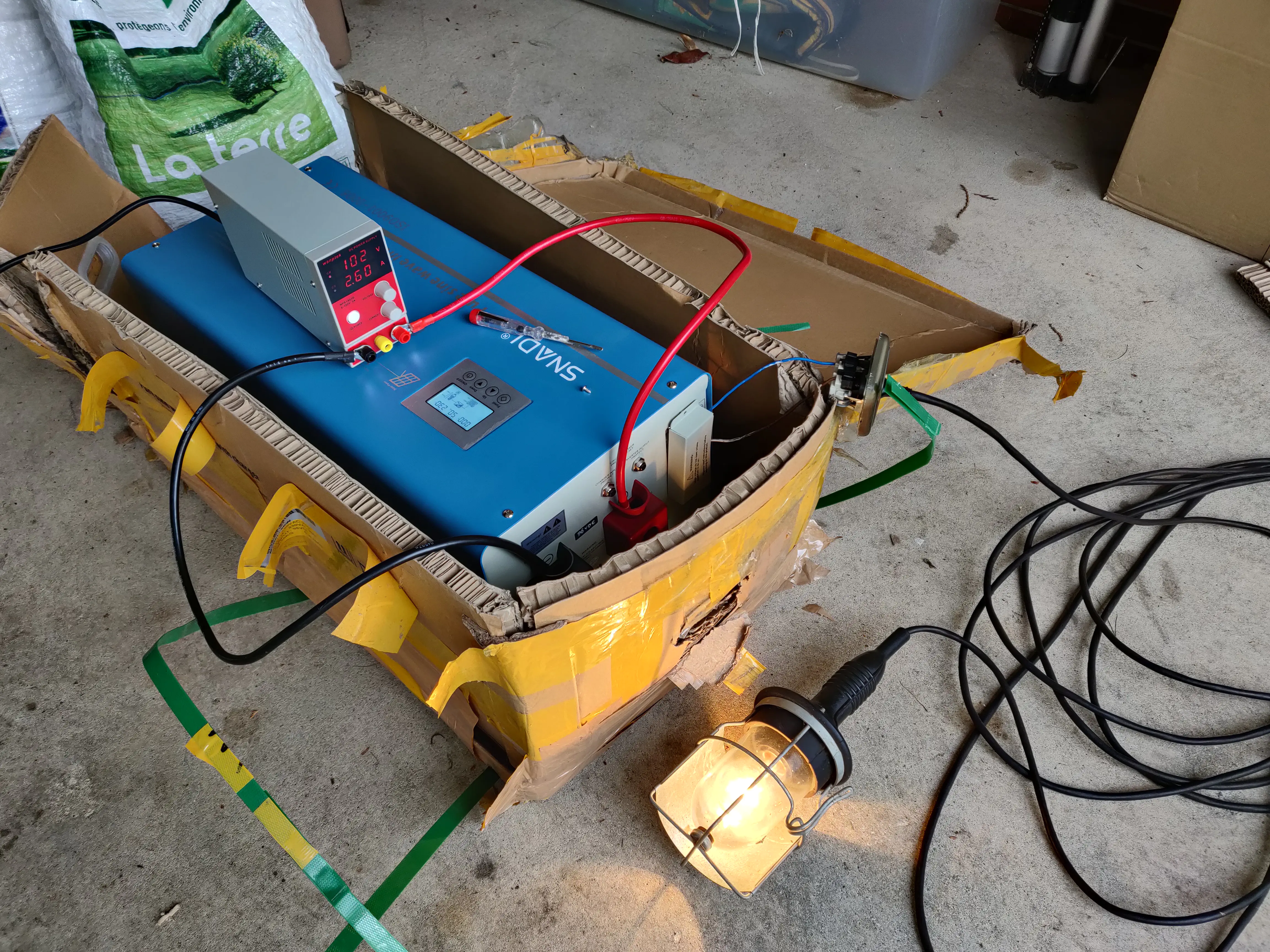

Finding components for our 96VDC nominal battery bank has been a challenge. We turned to the Alibaba marketplace to source high-power equipment directly from manufacturers in China. Before shipping everything to the shipyard, we set up a home lab to test it all.

MPPT Solar Chargers We selected the IPANDEE Mars series MPPT controllers, which are designed for commercial use in solar powered telecom towers. Each of these passively-cooled units can handle 5kW of solar power. We used a 100VDC stabilized power supply to confirm they function correctly.

DC to AC Inverters To create 220VAC power onboard, we chose an 8kW inverter from SNADI, which can also function as a battery charger. Our tests were successful, but we noted a significant no-load power consumption of 200W due to its heavy transformer.

To avoid this constant drain, we also sourced a smaller 3.5kW inverter from WZRELB. The plan is to use this more efficient inverter as a backup and as our primary “night” inverter for low-power needs.

With COVID-19 travel restrictions finally easing, we were able to get back to Alicante. While weekly video calls with the project management team are great, spending a few days on-site with Stuart and Eric was incredibly productive. We were able to take crucial measurements and finalize the locations for the electric motors and battery banks.

The “dirty” work is done! With the major fiberglass repairs complete, the Escargot has been moved from the dusty fiberglass workshop to the clean warehouse. This marks a new phase of the refit, focused on the installation of the solar superstructure, plumbing, electrical systems, and the new propulsion gear.

The refit of the Escargot has begun! After four months of hard work by the shipyard workers, we're excited to share our first major update. Our …

There have been many changes to our propulsion and energy storage system over the last 3 months. We exchanged regular emails with the owner of …