Refit Project Update - Q2 2021

The last three months have been a classic refit story of progress and patience. While the pace has been slower than we originally planned, we've …

Following a slower pace in the second quarter, we’ve implemented a new strategy of visiting the shipyard in Alicante monthly. This hands-on approach allows us to accelerate our specific refit tasks, make timely decisions on critical path items, and ensure the shipyard team maintains project momentum. Each visit also serves as an opportunity to transport equipment that has been prepared and tested off-site.

The custom stainless steel superstructure for our solar array, fabricated by a specialized company in Ukraine, has arrived at the shipyard in Alicante. The assembly process went smoothly, requiring only minor, planned adjustments and welding.

With the superstructure now complete, we are strategically delaying the installation of the 40 solar panels. This precaution will minimize the risk of damage while other major construction tasks are underway.

Several sections of the handrails had sustained damage and required extensive restoration. We capitalized on the availability of a stainless steel welder to complete these crucial repairs concurrently with the superstructure assembly.

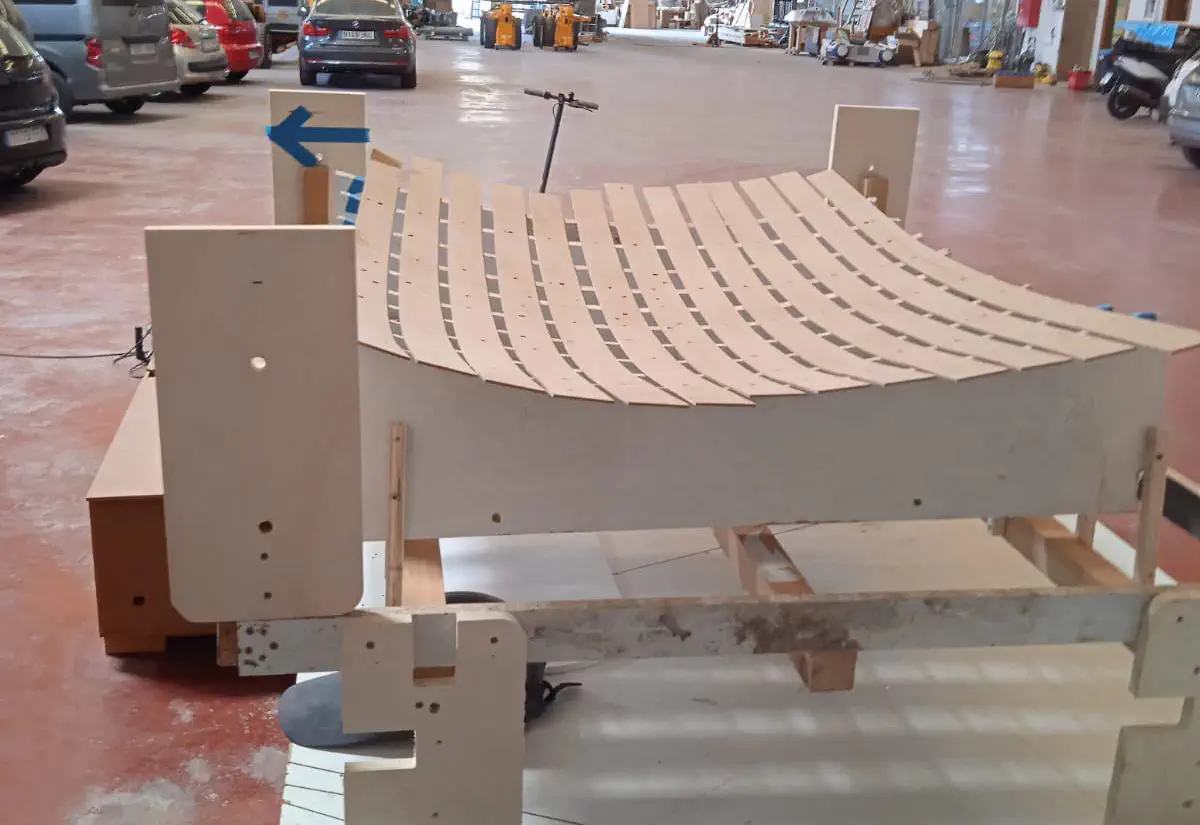

Our initial attempt to form the methacrylate windows in place was unsuccessful, as the material failed to conform to the precise curvature of the aft cabin. The shipyard team devised an innovative solution: a custom-built oven. This allows us to heat the methacrylate sheets slowly while they are secured to a mold, achieving the exact required shape. The initial tests have been highly successful, and full production of the windows is scheduled for the upcoming month.

We have standardized our waste management pumps by selecting the Jabsco 50890-1100 for all grey and black water tanks. All four pumps have been successfully installed. During this process, we discovered that two sinks were previously draining directly overboard. We have now rerouted their discharge lines into the grey water tanks to ensure full environmental compliance.

After finalizing the layout for the electric motors and battery banks, we have constructed and installed the custom fiberglassed-wood supports in the port-side engine room. These will provide a secure and robust foundation to support the 400 kg of batteries for the new power system.

A significant logistical effort was required to maneuver the new Fischer Panda AGT18000 backup generator into position, due to its 265 kg and its large size. The process involved careful planning to move the unit through the boat’s interior and down into the starboard engine room, for which a custom wood ramp was constructed.

To regulate the 3 phases AC from the generator to DC, there is an electrical box named the VCS that must be installed near the generator, as the diodes of this VCS are water cooled on the raw water circuit of the generator. We reviewed all the possible options to position this box, and we decided to put it over the water line in the same cabinet as the electric hydraulic pump.

The installation of our new 24V DC electrical system has commenced, starting with the interior lighting. We have begun fitting the new low consumption LED lights and switches throughout the vessel.

Our new monthly cadence of shipyard visits has proven highly effective. Each trip included productive planning sessions with the technical project team to outline upcoming tasks. We also utilized our time on-site to take extensive measurements, which is crucial for continuing detailed design work, such as electrical wire routing, while we are off-site.

These trips also allow us to deliver pre-tested, assembled or custom-built components from our home workshop, such as the large 96V DC circuit breaker shown here.

The last three months have been a classic refit story of progress and patience. While the pace has been slower than we originally planned, we've …

The refit of the Escargot has begun! After four months of hard work by the shipyard workers, we're excited to share our first major update. Our …