Refit Project Update - Q3 2021

Following a slower pace in the second quarter, we've implemented a new strategy of visiting the shipyard in Alicante monthly. This hands-on approach …

The fourth quarter marked a major turning point in our refit project with the arrival of the complete electric propulsion system in Alicante. This milestone has allowed us to schedule the final installation tasks and set a firm date for our initial sea trials: the week of January 31st, 2022.

With the boat having been de-registered from the Spanish flag at the time of purchase, we are now expediting the French registration process for Escargot. This is a critical step to legally operate on the water and to secure the necessary liability insurance for our upcoming tests. All required administrative work is currently underway with French customs and maritime authorities.

Over several weeks, the underwater sections of the hull have been meticulously prepared. The painting team first applied a light grey epoxy primer to create a durable, protective barrier. This was followed by the application of a black Ecofleet 530 antifouling coat to prevent marine growth.

The newly fabricated stainless steel rudders have been installed within the rudder shaft tubes. The hydraulic cylinders are now mounted, completing the primary assembly for the steering control system of Escargot.

The new four-blade propellers have been fitted to the propeller shafts. To protect against galvanic corrosion, both the propellers and shafts have been equipped with sacrificial anodes.

The GRL DNH19 400A main switch disconnectors, which we reconfigured to create four parallel 400A contacts leading to a bus bar, have been installed. They are housed in metal electrical cabinets mounted in the port-side hull near the battery banks. These heavy-duty switches are designed for isolating the batteries from all 96V DC consumers (motors, inverter) and producers (solar MPPTs, AC charger, generator) during maintenance.

Following successful bench-testing of the entire propulsion system, we have installed the electric motors. They are secured on their supports with anti-vibration mounts, and the motor controllers are mounted directly above them. With both port and starboard motors in place, we are now finalizing the precision alignment with the propeller shafts.

The four custom battery boxes have been securely installed on their dedicated supports at the bottom of the port-side hull.

We have installed Mota E065-411-4/CN heat exchangers in the aft locker of each hull. A closed-loop coolant circuit will circulate through the motors and controllers, transferring heat to raw seawater via the exchangers. Sizing the raw water pump was challenging due to unknown heat loads. To maintain a low-voltage environment in the aft lockers, we selected the 24VDC Jabsco Cyclone 50840-2024 pump, capable of 110 liters per minute. We will use generic coolant circulation pumps used in trucks. The upcoming sea trials will validate if this setup provides sufficient cooling.

The hydraulic contractor has delivered and installed the electric pump that pressurizes the steering circuit. The 3kW, 24VDC motor has a higher potential power consumption than anticipated. The actual energy usage for the steering system will be determined during sea trials.

The shipyard’s mechanic has completed the precise alignment of the propeller shafts to the electric motors. The stern tubes have been sealed, marking the final step in ensuring Escargot is fully watertight and ready for launch.

All aft cabin windows have been successfully thermoformed and bonded in place using black Sikaflex sealant. For improved ventilation, we replaced one of the windows in the flattest section of the cabin with a Vetus 70x70cm hatch.

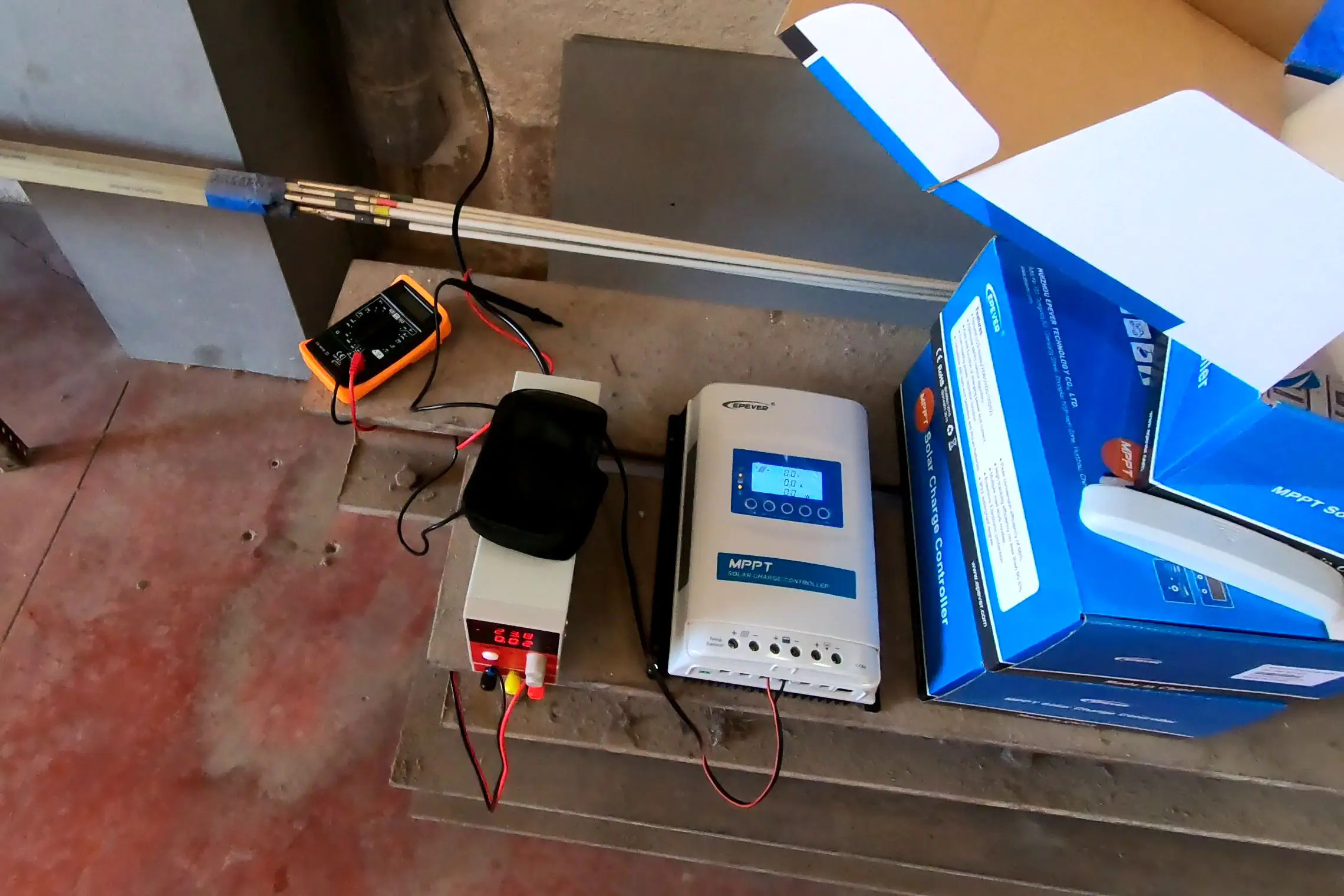

To charge our 12VDC and 24VDC sealed lead-acid battery banks from the main 96V lithium bank, we explored several options. After an initial test with a 100-240V AC charger that failed to accept a DC input, we developed a solution using solar MPPT charge controllers as DC-to-DC chargers. This approach offers the benefit of proper multi-stage battery charging, a significant advantage over simple DC-DC converters. We selected three EPEVER XTRA 3415N XDS2 chargers, which can handle up to 150V DC on the input side, making them compatible with our high-voltage system. They have been tested and configured for our specific battery banks.

Following a slower pace in the second quarter, we've implemented a new strategy of visiting the shipyard in Alicante monthly. This hands-on approach …

The last three months have been a classic refit story of progress and patience. While the pace has been slower than we originally planned, we've …