Refit Project Update - January 2022 - Ready for Sea Trials!

While only a month has passed since our last update, the progress has been immense. We have completed a multitude of critical tasks, and Escargot is …

We’re back in the warehouse after a week of semi-successful sea trials. The past few months have been productive. We’ve brought our solar charging system online, installed the DC-to-DC chargers for our 12VDC and 24VDC battery banks, and made significant headway in diagnosing the propulsion system lack of power.

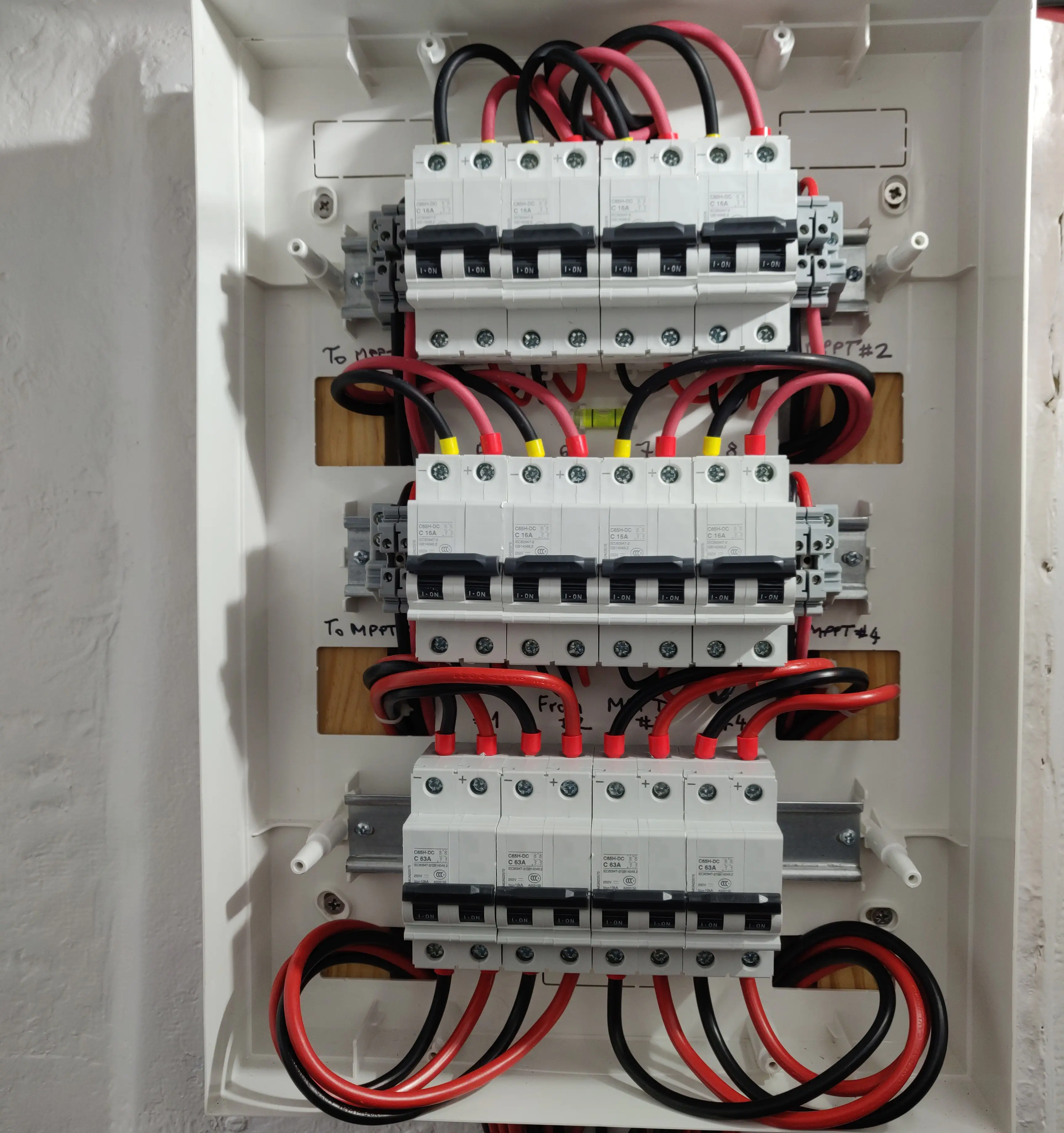

We have successfully completed the wiring of our solar array. This involved installing breakers to combine the solar array strings leading to the MPPT chargers and connecting the chargers to the 96VDC bus bar switches.

While the wiring still needs to be tidied, it was incredibly rewarding to see the warehouse’s overhead lights activate the “solar” charging on our MPPT controllers.

A new electrical box with DC breakers has been installed to accommodate upcoming circuits. These will power the 220VAC inverters and the DC-DC chargers for the 24VDC and 12VDC battery banks. A third circuit will be dedicated to computer equipment that can run directly on 96VDC, as we have verified their 100-240VAC switching power supplies function correctly at this voltage.

To maintain our low-voltage battery banks, we are utilizing dedicated MPPT controllers. These controllers draw power from our main 96VDC battery bank to keep the 12VDC and 24VDC systems fully charged.

Our electric motors were manufactured by the Italian company, FIMEA. Upon inspection, we located the nameplate on the motors and discovered that both units have an identical serial number.

After contacting FIMEA for clarification, we learned that our two motors were sold as a single integrated system on a single shaft, designated as a FIMEA N80X2. Critically, the motor windings were designed for 144V operation, not our 96V system. This voltage mismatch is the primary reason for the underperformance. We have since recalculated the power and torque curves for our N80X2 halves at 96V. The revised projections indicate that we can expect approximately 8kW of continuous power and 140Nm of torque.

We have begun researching replacement motors. FIMEA produces the N80L model, which is designed for 96V and delivers 30kW of continuous power (50kW peak). We are currently assessing whether the slightly larger dimensions of the N80L will fit our existing space as we consider placing an order.

Our initial splash was cut short due to water ingress caused by an improperly mounted shaft stern tube. This issue has now been fully rectified.

With the major structural and propulsion work nearing completion, we have shifted some of our focus to the interior. We’ve started with a thorough cleaning and have begun repairs, such as refinishing the wall in the forward port side shower. Our goal is to make the cabins habitable for living aboard in the near future.

While only a month has passed since our last update, the progress has been immense. We have completed a multitude of critical tasks, and Escargot is …

The fourth quarter marked a major turning point in our refit project with the arrival of the complete electric propulsion system in Alicante. This …