Refit Project Update - Q2 2022

Progress over the last three months has been focused heavily on resolving our propulsion issues. The highlight of this quarter is that we have …

The third quarter of 2022 was a period of significant progress on our vessel’s refit. With the arrival of our new FIMEA N80L motors at the end of July, we worked diligently to install, configure, and test the new propulsion system in preparation for a late October sea trial. This update covers the key milestones achieved during this busy period.

A major focus of this quarter was the installation of our new FIMEA N80L electric motors. The motor supports in the engine bays required modification to accommodate the standard marine mounts of the new motors, with the motor silent blocks at the same level as tge the propeller shaft.

Once the motors were securely installed on their modified supports, they were connected to the DMC controllers using high-quality Radsok connectors.

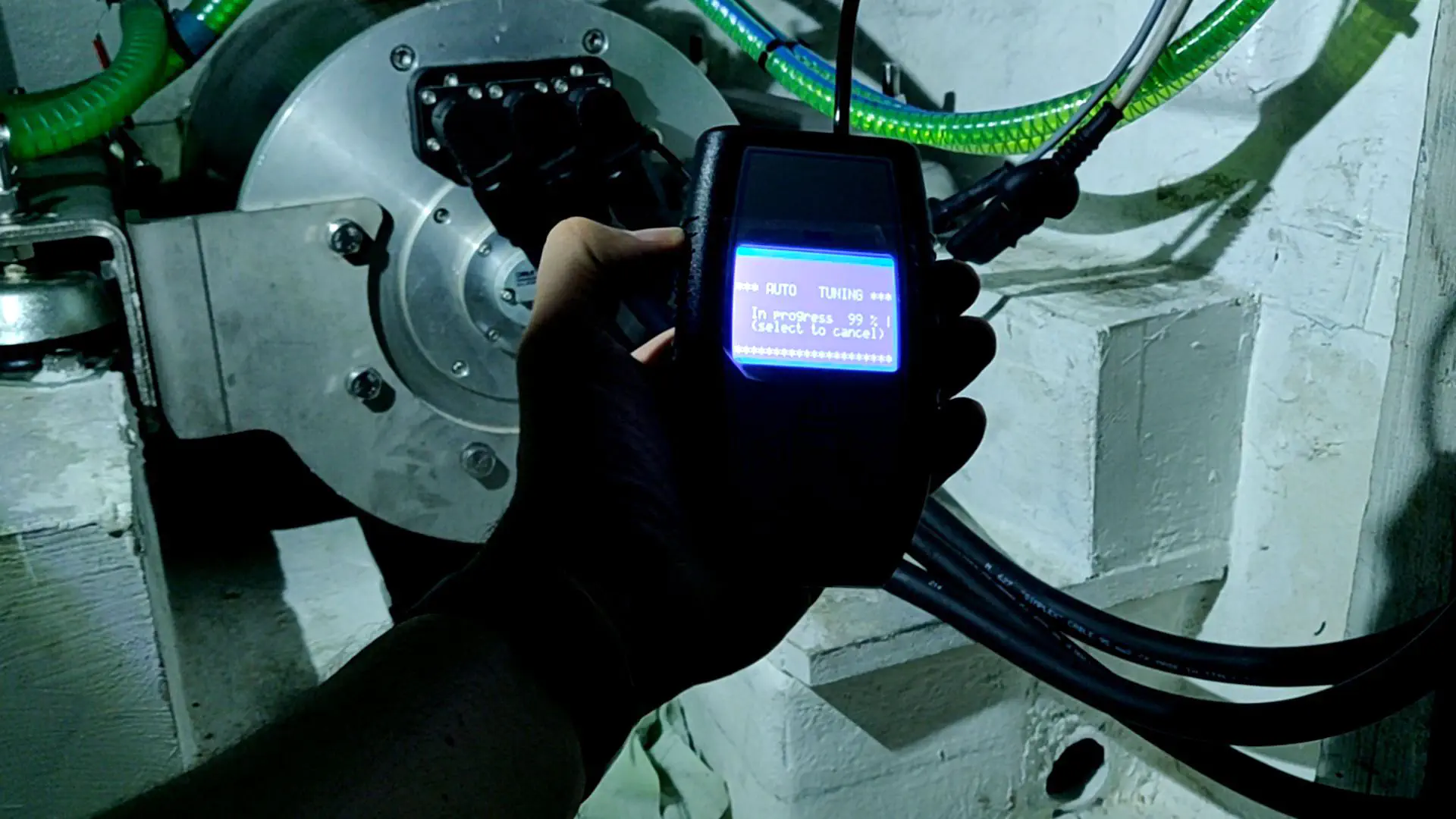

The DMC controllers feature a convenient auto-tuning function. Using the DMC calibrator handheld controller, we entered the necessary motor parameters to initiate the process.

With the motors disconnected from the propeller shafts, the auto-tune sequence was successfully executed on each unit. This process allowed the controllers to learn the specific characteristics of each motor, ensuring optimal performance.

To improve the reliability of the coolant circulation for the motors and controllers, we replaced the previous generic pumps with Johnson Pump SPXFlow CM10P7-1 models. These new magnetic-driven, seal-less circulating pumps are designed for longevity.

Following our sea trial in February, we discovered stress cracks in the fiberglass near the swim platform stairs.

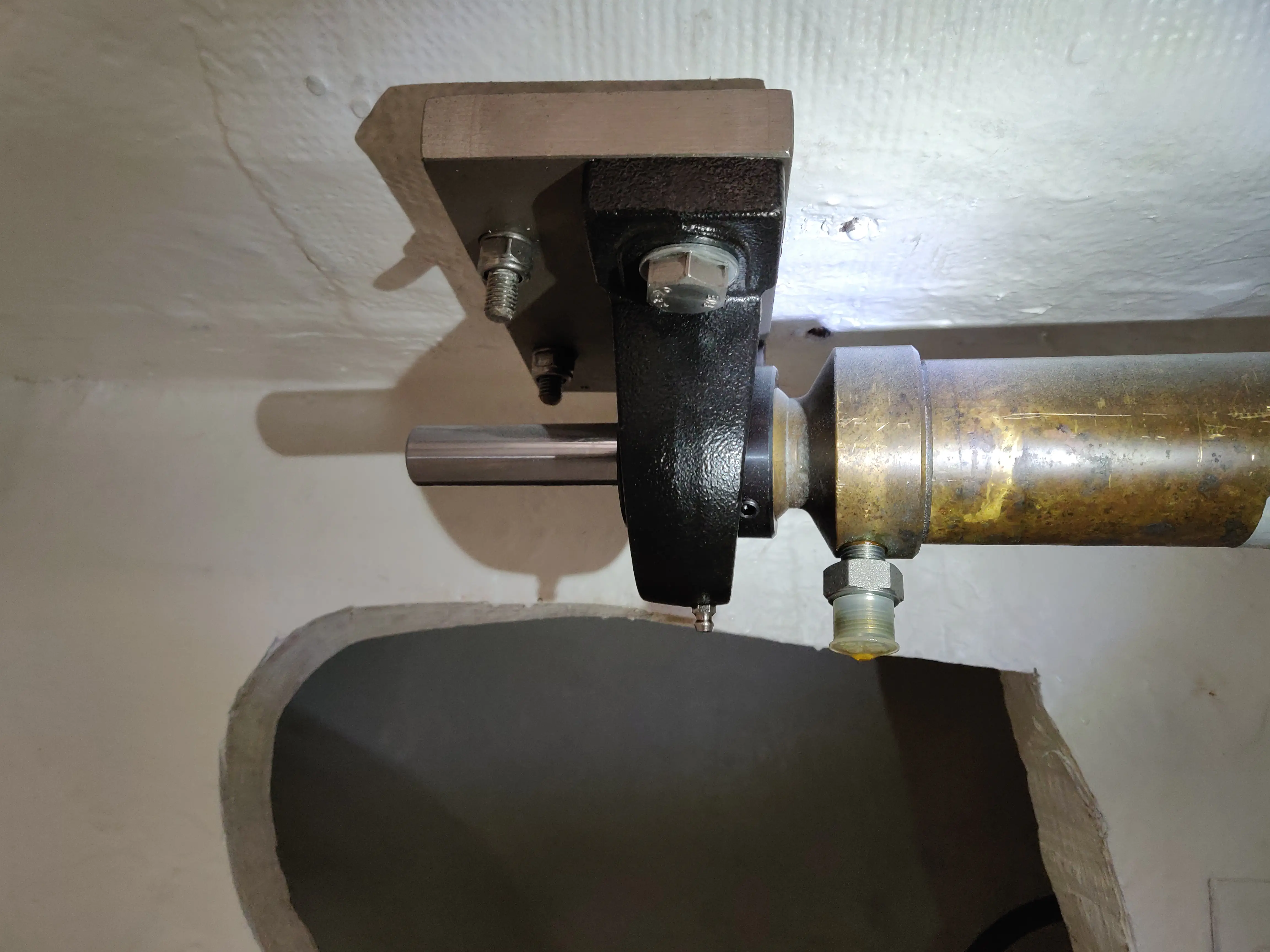

The cracks were located directly above the attachment plates for the hydraulic steering cylinders. These areas have now been reinforced to prevent future cracking from the forces exerted by the steering system.

A custom plexiglass shield was installed to protect the Vevor 24V double-acting hydraulic pump for the anchor locker. This will prevent water from splashing onto the pump during anchor and chain washing.

The throttles supplied with our initial propulsion system felt insubstantial and were not waterproof. In contrast, the original Dean Catamarans diesel engine throttles were robust and well-designed. We undertook the task of modifying these original throttles for use as analog inputs for the DMC motor controllers.

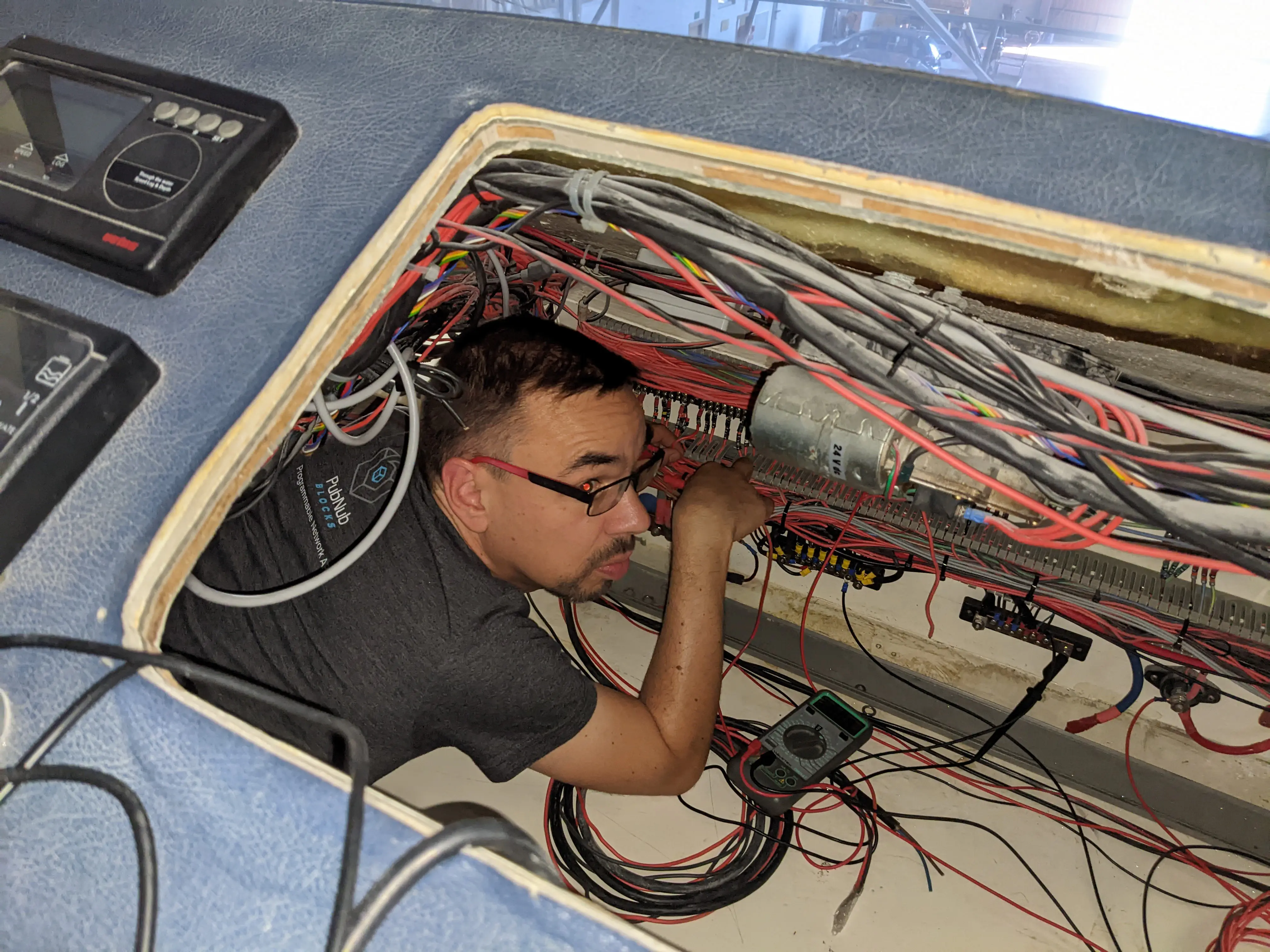

As the original electrical schematics for the 24VDC and 12VDC circuits were unavailable, we began the process of creating our own. The objective is to remove redundant wiring and to have a comprehensive record of the remaining circuits.

This essential task required navigating some of the more confined spaces of the vessel.

The collected data is being systematically entered into a spreadsheet for clear and accessible documentation.

With the vessel on the hard, it has been an opportune time to address general cleanup. We have taken this opportunity to remove all components of the old air conditioning systems, including piping and other parts, to reduce clutter and make space for future installations.

This process also involved accessing and cleaning out smaller, hard-to-reach areas.

Our two inverters have been connected and configured. This is a temporary setup, as a selector switch for choosing between inverter 1 and 2 for our 220VAC supply is still to be installed. However, the core systems are operational.

For our onboard hot water needs, we have installed a residential 220VAC 80-liter water heater. This model includes built-in Wi-Fi and a mobile application for convenient remote management, eliminating the need to access the bilges for configuration.

The port side aft door has been a persistent issue due to its weight and malfunctioning mechanical parts. As a potential temporary solution, we have replaced the original door with a custom wooden panel featuring a methacrylate window and new locks. We are still evaluating options for the long-term restoration of the original door.

We are pleased with the significant advancements made this quarter and are looking forward to our upcoming sea trials. Stay tuned for our next update.

Progress over the last three months has been focused heavily on resolving our propulsion issues. The highlight of this quarter is that we have …

We're back in the warehouse after a week of semi-successful sea trials. The past few months have been productive. We've brought our solar charging …