Refit Project Update - Q1 2023

The last three months have been very productive. We've made significant progress, giving the boat a fresh new look and integrating crucial systems …

Everything was tracking well for our May 15th splash, until we hit a major roadblock. In early May, we decided not to continue with the NMC batteries due to safety concerns. Consequently, we canceled the launch and shifted our focus to removing the four battery boxes from the port side hull and researching marine-grade, safe alternatives for Escargot.

The “cell too hot” errors on the BMS—which caused cell balancing and charging to stop—became increasingly severe. The issue eventually caused the battery to discharge much lower than acceptable limits. At that point, we decided we could no longer trust the system. The BMS manufacturer provided no support, and the battery integrator failed to acknowledge the design flaws.

As we were already in a legal dispute regarding the former electric motors (sold as 50kW peak but actually 16kW peak), we added the dysfunctional battery management design to the case. We understand that reaching a resolution will take time, so we decided to proceed with the battery removal and replacement at our own expense for now. We were simply not comfortable heading back to sea with unsafe and unreliable energy storage.

Each of the four batteries was safely removed from the port side hull and transported to the warehouse using the shipyard forklift.

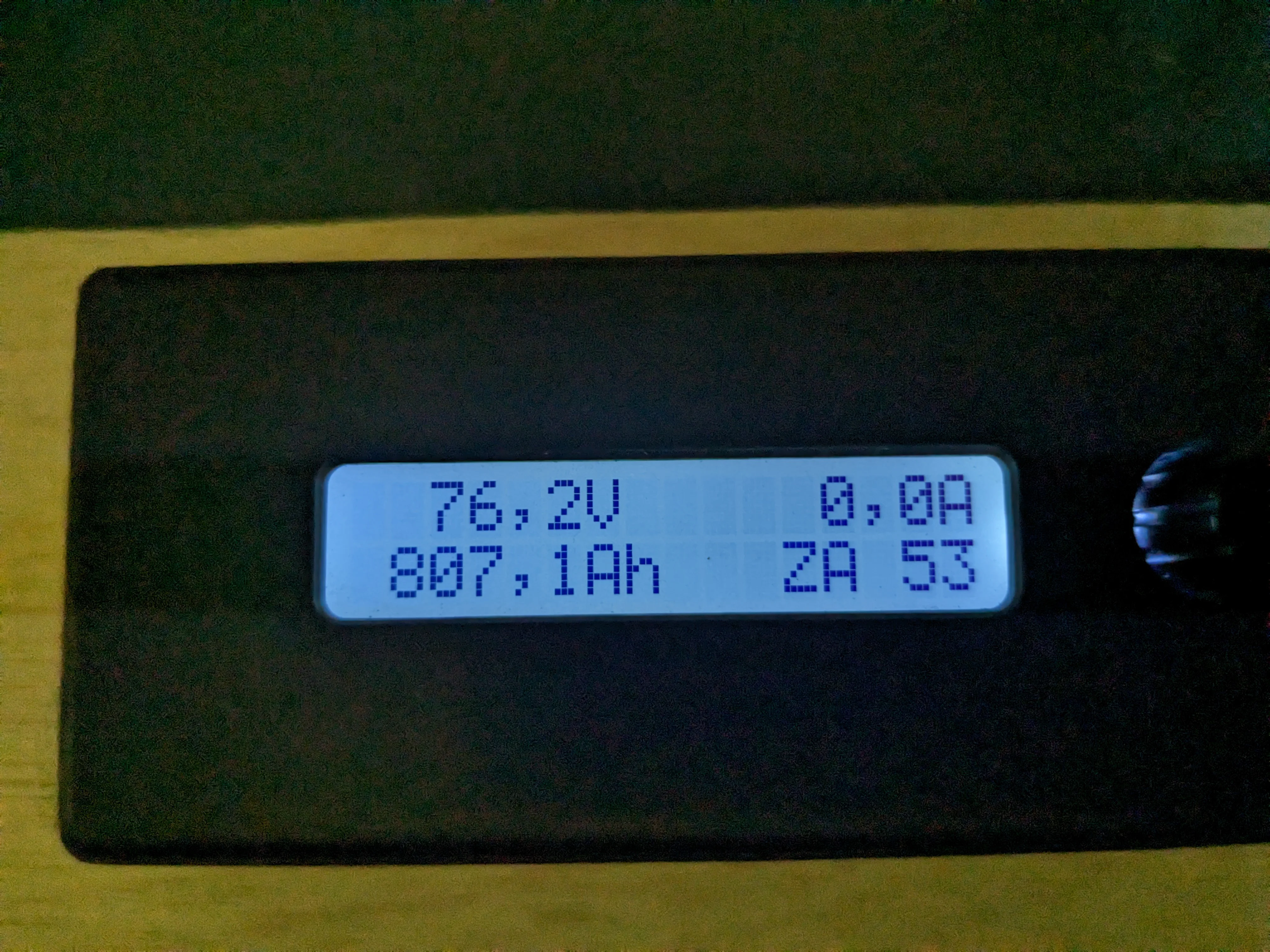

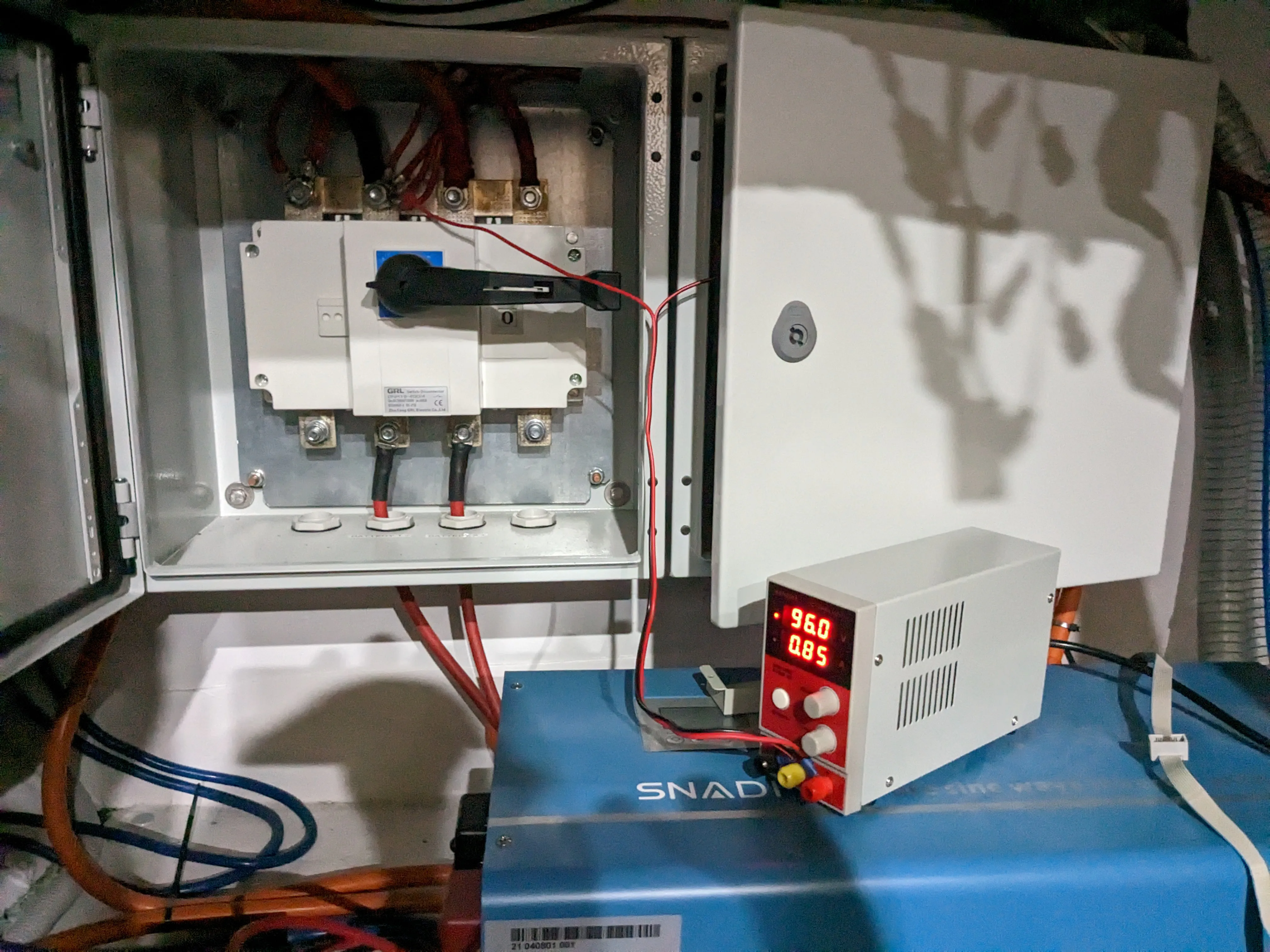

With no batteries onboard, we needed a solution to keep the systems running. We installed the stabilized power supply from our test bench to provide 96VDC directly to the busbar on the main switches. This unit provides up to 3A, which is sufficient to power our DC-DC charging MPPT controllers (to keep our 24VDC and 12VDC banks charged) and power the other small electronics connected to the 96VDC high-voltage bank.

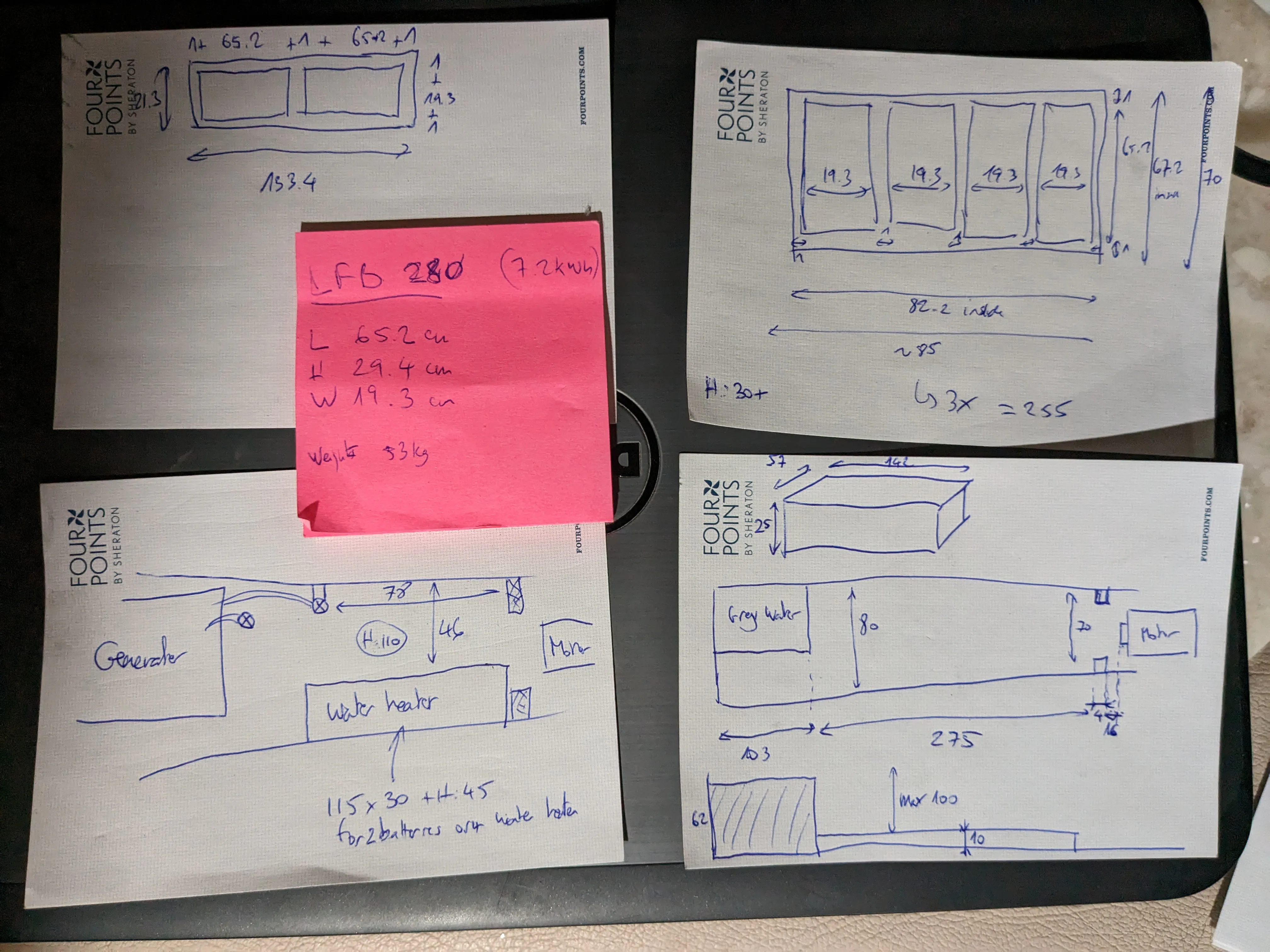

Our search for replacement batteries was significantly narrowed down by our 96VDC voltage requirement. Our final two candidates were both from Dutch companies: the Mastervolt MLI Ultra 24/6000 and the MG Energy Systems LFP 24V 280. Ultimately, we selected MG Energy Systems because their system offered excellent modularity via the MasterLV and SmartLink products, and the total cost for the same energy capacity was slightly lower.

The next step was designing the layout within the hulls. To improve weight distribution, we decided to install 8 batteries in the port side hull and 4 in the starboard side hull. We will have three groups of four batteries wired in series. Each group will be housed in a custom-built metal box and connected to a MasterLV module feeding the 96VDC busbar. A SmartLink unit will orchestrate the three MasterLV controllers.

In Spain, it is necessary to purchase through a local reseller rather than buying directly from a foreign vendor. We requested quotes from several resellers and selected one near Murcia. They offered the best pricing (15% off the official catalog price) and excellent English communication. Just as we were preparing to order, MG Energy Systems released the LFP 304 model. It features the same form factor as the LFP 280 but with an additional 600Wh of capacity. We placed the order today and expect delivery in 2 to 3 weeks.

The original light mast of the Dean Catamarans JAG 530 no longer fits atop the “whale tail” fiberglass superstructure, as our new aft solar roof now occupies that space. Additionally, our port and starboard navigation lights have been relocated from the sides of the whale tail to the sides of the aft solar roof.

We reviewed the Convention on the International Regulations for Preventing Collisions at Sea (COLREGs) to determine the necessary height for the navigation and anchor lights. For a vessel of our size (under 20m), the masthead light must be at least 2.5m above the gunwale and 1m above the sidelights. We constructed a new mast to meet these requirements using a PVC tube mounted on a residential roof antenna fixture.

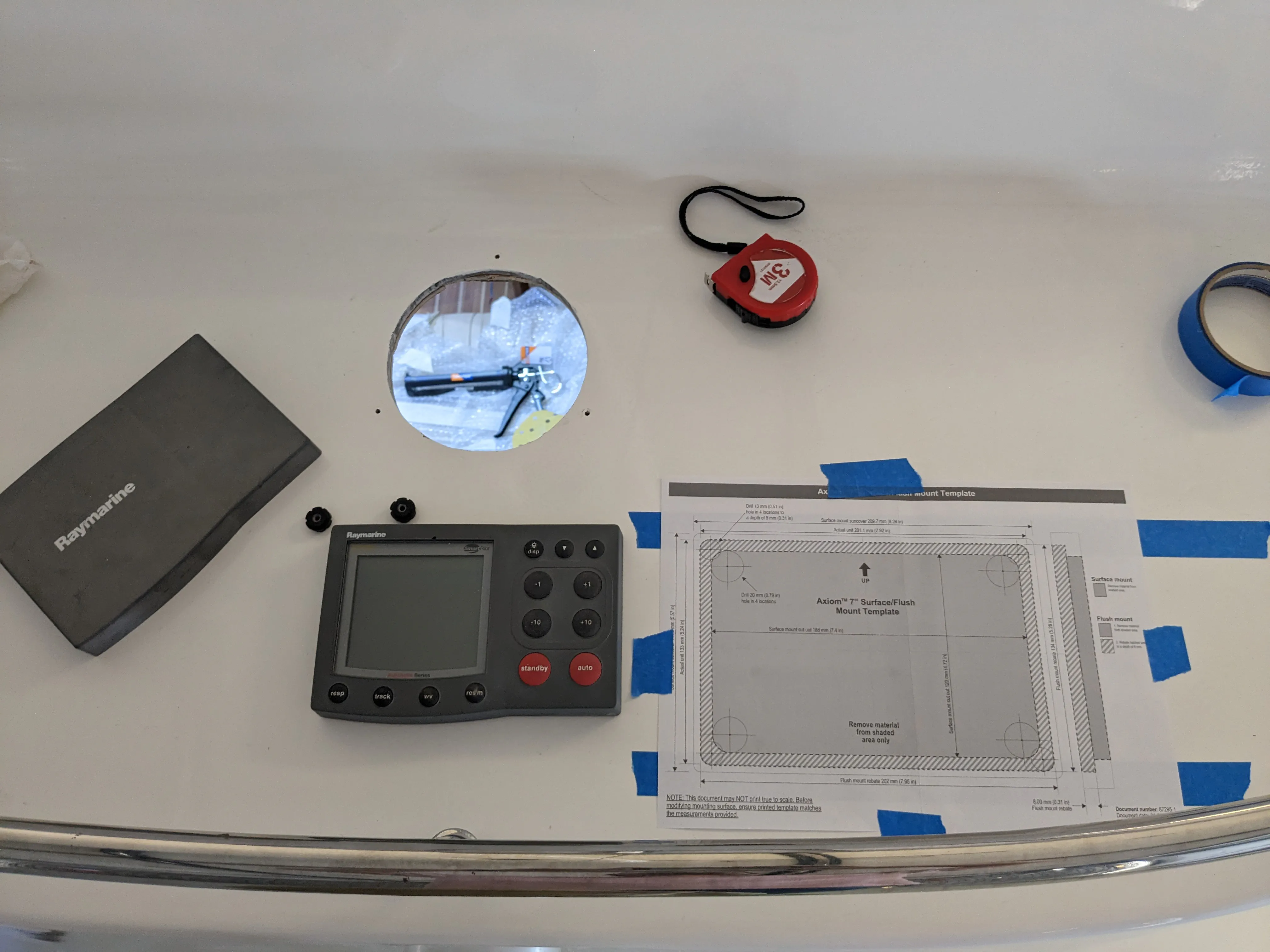

Using the template provided by Raymarine, we cut the opening for the Axiom chart plotter on the flybridge console.

After drilling four pilot holes in the corners and making straight cuts with the jigsaw, the Axiom chart plotter was successfully installed and booted up.

With the new mast up, the chart plotter running, and the new battery order confirmed, we are finally feeling back on track. While the delay to switch batteries was frustrating, we are confident that prioritizing safety and reliability was the right call.

We are now counting down the days until the new MG Energy Systems batteries arrive in 2 to 3 weeks. Once installed, we will be ready to power up and finally get Escargot back in the water.

The last three months have been very productive. We've made significant progress, giving the boat a fresh new look and integrating crucial systems …

The last two months have been full of activity and progress! Having Escargot on the water for nearly six weeks was an invaluable experience, …