Refit Project Update - Q2 2023

Everything was tracking well for our May 15th splash, until we hit a major roadblock. In early May, we decided not to continue with the NMC …

We are finally ready to splash! We have installed our new energy systems, completed the remaining safety equipment, and prepared the amenities for liveaboard life.

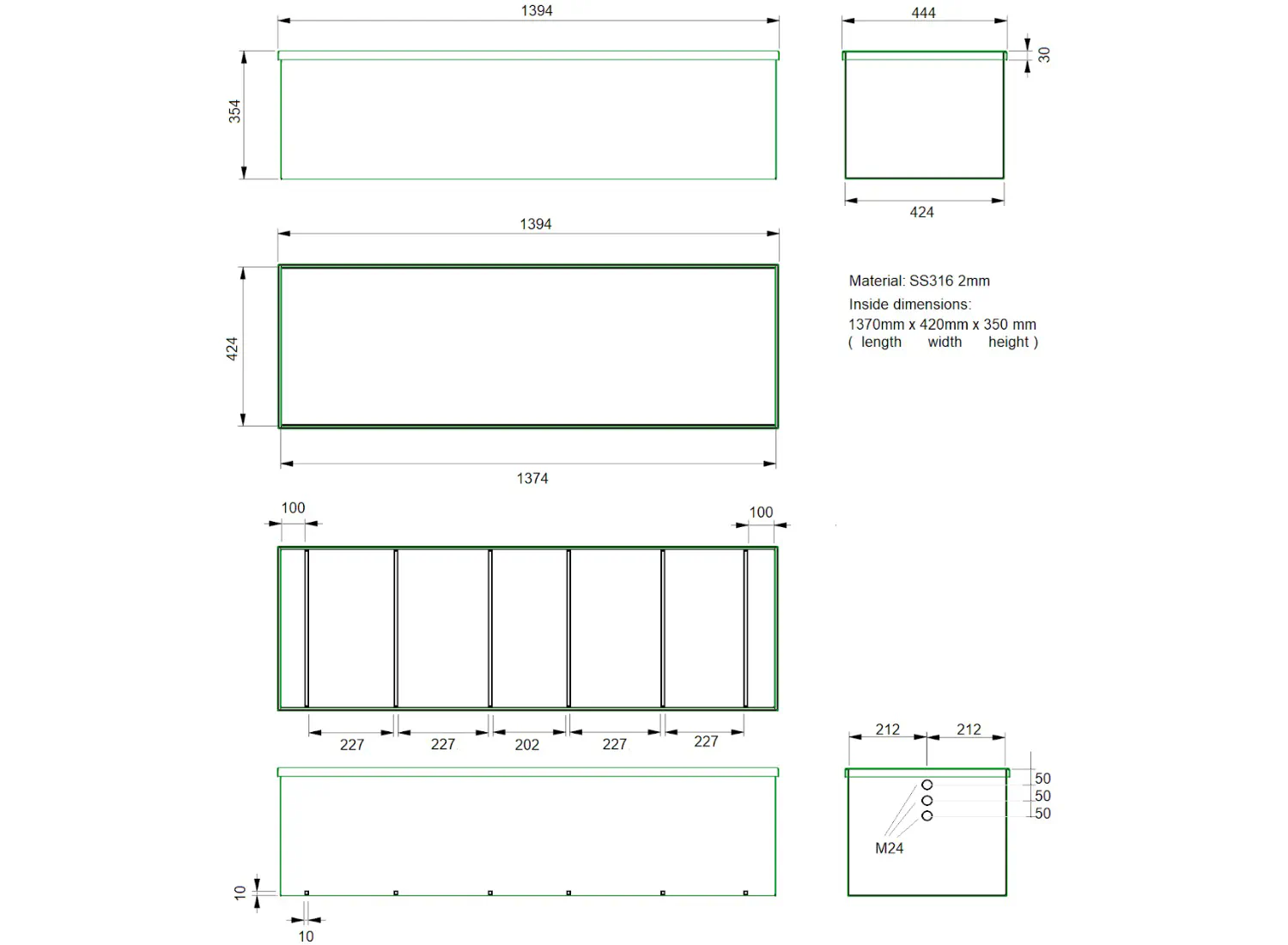

MG Energy Systems recommends housing batteries in metal boxes, especially when they are installed below the waterline. Using their documented spacing requirements, we designed a battery bank layout that fits perfectly within our hulls.

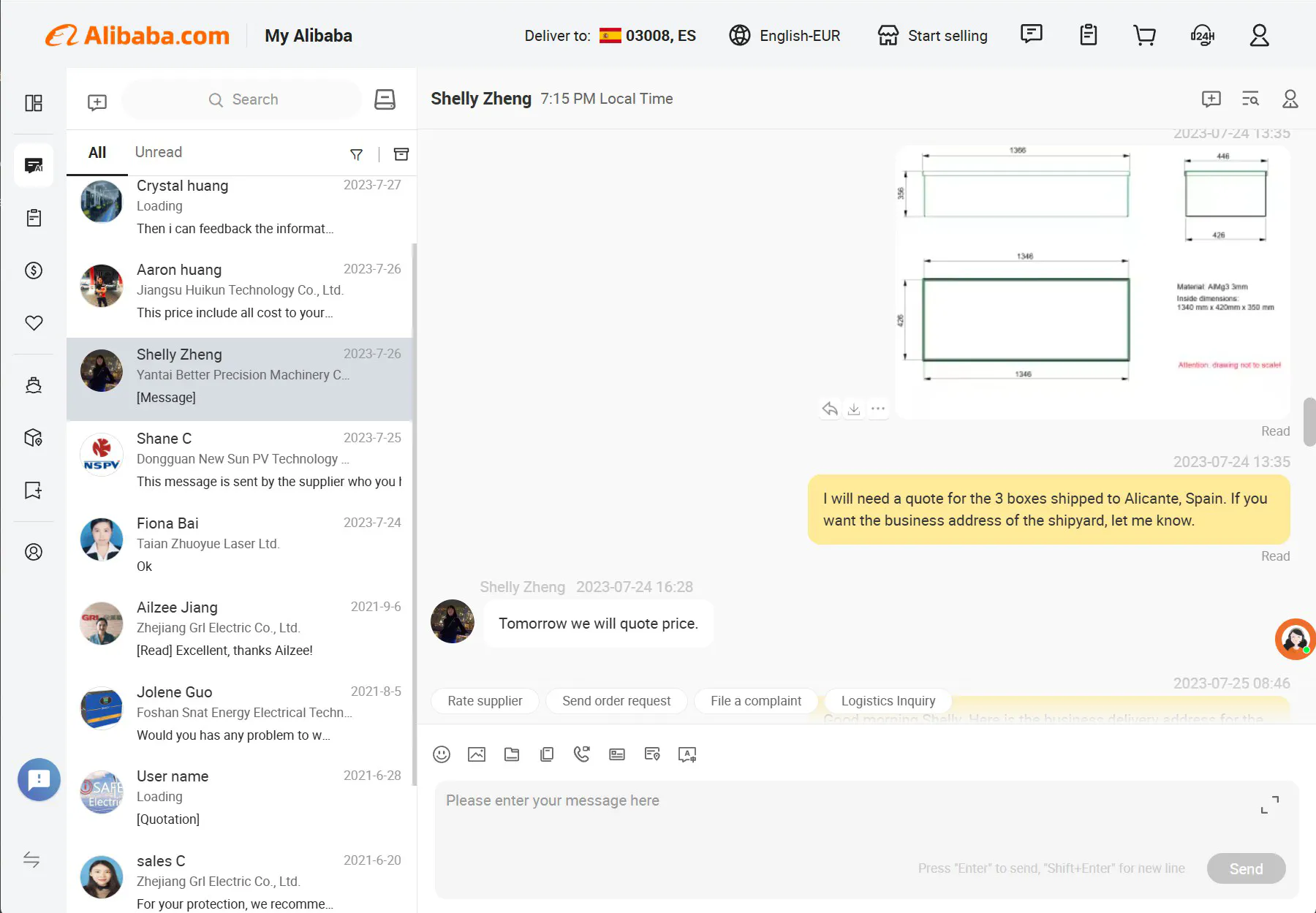

We requested pricing and lead times from Inoxcon, a local company in Alicante, and sent the same drawing and requirements to the Alibaba marketplace to compare prices, timelines, and material recommendations. While quotes from Chinese manufacturers were generally less than half the price of the local manufacturer, the shipping costs, long lead times, and administrative costs to clear customs meant the total savings would likely only be around 30%. Ultimately, we decided to work with Inoxcon. However, the research confirmed that we could safely reduce the thickness of the 316 stainless steel from 2mm to 1.5mm.

The Alibaba marketplace was a valuable resource for researching MPPT controllers, inverters, and large circuit breakers—components that are often hard to find for 96VDC systems. However, for custom-built metal boxes, it was definitely better to work with a local shop rather than shipping large, empty boxes halfway around the world.

The batteries were delivered well-packed on two pallets, with a separate box for all the electronic equipment.

Since each battery weighs 54kg, moving all 12 of them into Escargot via the temporary aft stairs was not an option. The shipyard forklift lifted them up four at a time, positioning them to be carried into the hulls.

Once the batteries were positioned in their stainless steel boxes, we installed the MasterLV units. These act as the main BMS controller for each group of four batteries, housing the safety contactor and fuses. While they can function as a busbar for parallel batteries and consumers, in our application, each MasterLV manages a single string of four batteries. Each unit is then connected to the positive and negative busbars of the 96VDC circuit breaker.

The next step was cutting the cables to the correct length, crimping the lugs, and sealing them with heat shrink.

We then connected the cables with nuts, strictly following the MG Energy Systems torque specifications using a torque wrench.

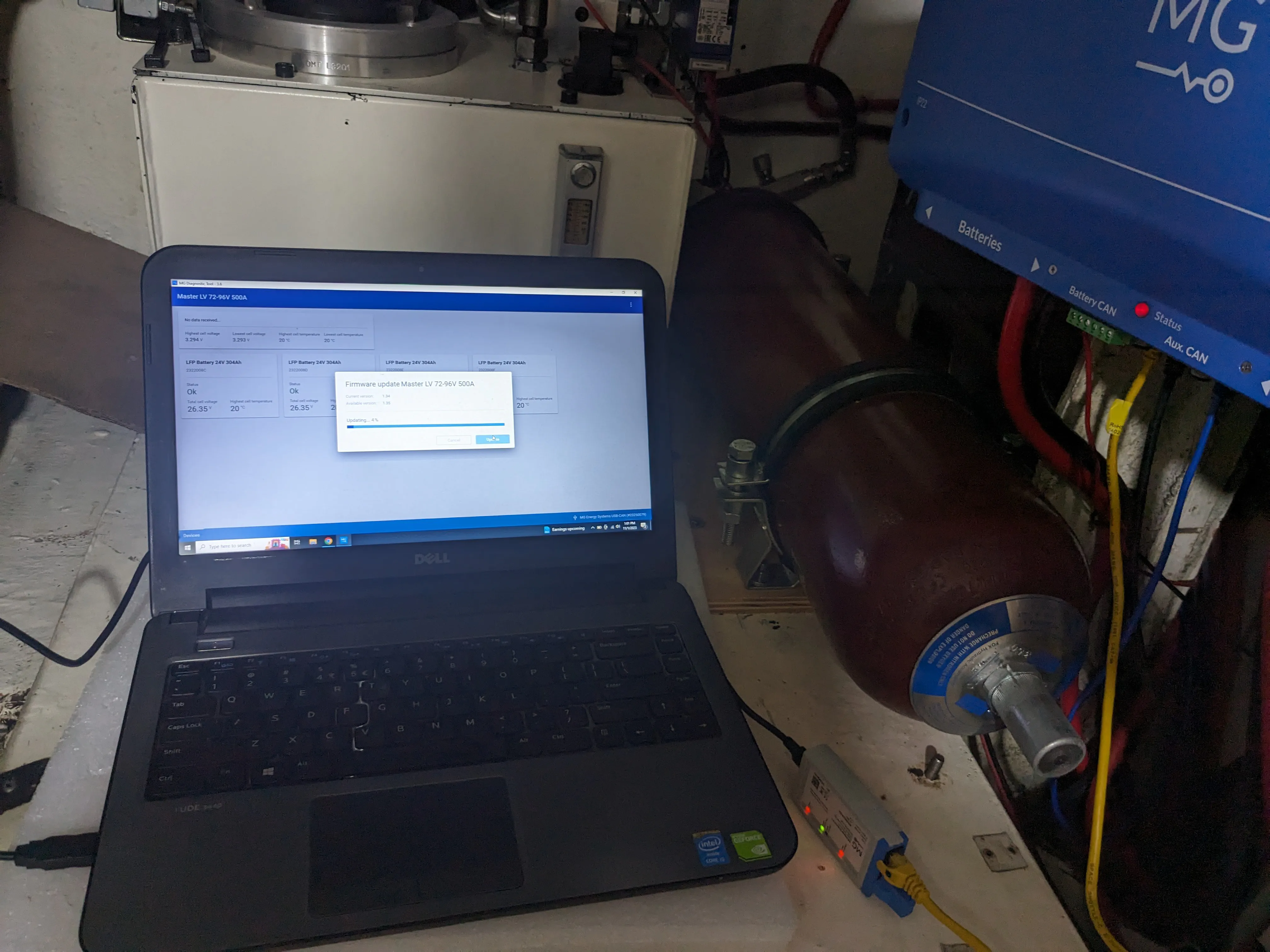

Finally, it was time for commissioning. We initially turned on each MasterLV individually, with a laptop connected to the CAN bus to perform firmware updates and monitor all parameters. We started in the port side hull, where the two MasterLV units are positioned right next to the batteries.

We then repeated the process in the starboard hull, where the MasterLV for the third bank is located in the technical closet alongside the hydraulic steering and generator regulator diodes.

With all three MasterLV units active and verified to have matching output voltages to avoid any inrush current between banks, we switched on the main circuit breaker busbars to connect all 3 banks together. We then configured the SmartLink module to manage the three parallel banks.

The final step in the setup was connecting one of the SmartLink relay outputs (configured to close on “allow-to-charge” status) to a custom-built set of four static relays. This custom electronics board uses IXFN160N30T MOSFETs, chosen for their low RDSon resistance. Controlled by the SmartLink, these MOSFETs cut the solar panel strings when the batteries are fully charged. This system acts as a necessary fail-safe, adding a layer of security on top of the MPPT chargers’ internal voltage detection.

We focused on the two starboard cabins to ensure they were comfortable for sleeping. First, we restored and installed the bedside tables.

Next, we added wood planks to allow air circulation under the mattresses, which helps limit mold and mildew formation.

Finally, we modified the 160cm wide IKEA mattress to match the rounded shape of the bed frames in both cabins.

We received our washing machine, two fridges, and freezer. We searched for a standard home washing machine that was lightweight and shallow. The “Ibiza” model from Universal Blue was a good match dimensions-wise, and the Balearic Island-themed name felt perfect for our boat. For the fridges and freezers, the key decision factor was physical dimensions, as we wanted to minimize structural modifications to the cabinetry.

The washing machine fit easily. We then passed the freezer through the former dishwasher opening, followed by the fridge through the same path. We will not be installing a dishwasher; instead, we plan to build additional storage in that space.

In the bar salon, the new fridge was a perfect fit.

We painted the light mast we built a few months ago using the same International One Up primer and Toplac Plus as the hull. We fitted our Glamox Aqua Signal Series 34 anchor and navigation light, and it looks great!

We ordered new decals for the boat name and registration number to ensure compliance with French Flag regulations.

With this last touch, Escargot is ready to go back to the water.

Everything was tracking well for our May 15th splash, until we hit a major roadblock. In early May, we decided not to continue with the NMC …

The last three months have been very productive. We've made significant progress, giving the boat a fresh new look and integrating crucial systems …